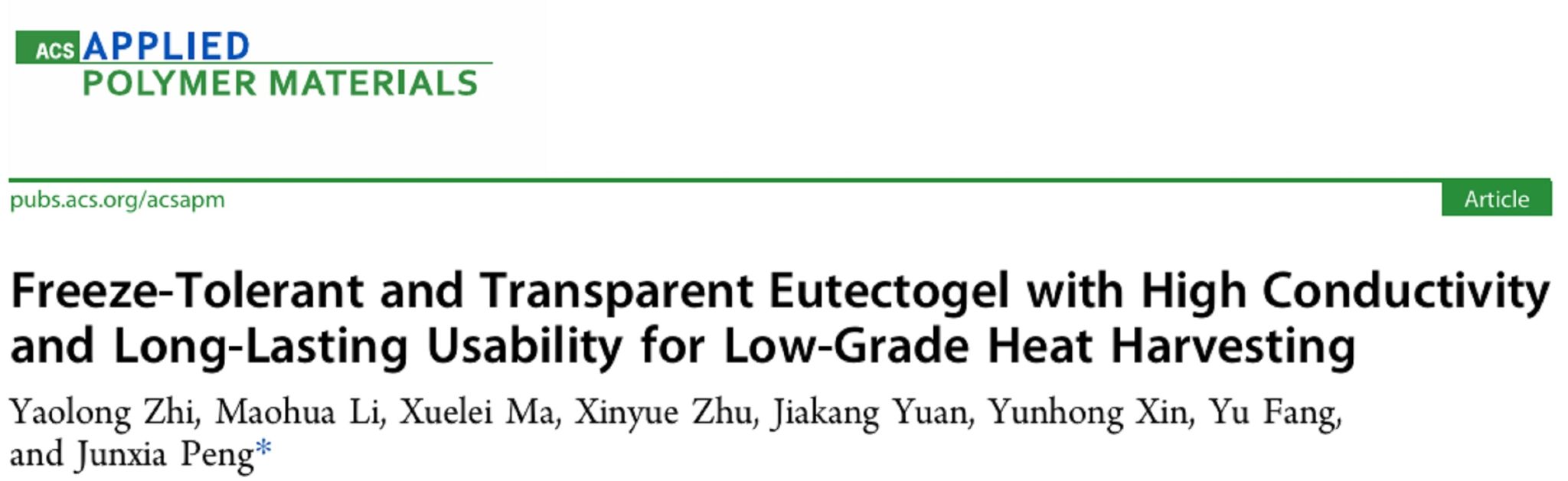

Yaolong Zhi Maohua Li, Xuelei Ma, Xinyue Zhu, Jiakang Yuan, Yunhong Xin, Yu Fang, Junxia Peng. ACS Appl. Polym. Mater. 2025, 7, 4383−4393, Doi: 10.1021/acsapm.5c00097

The reuse of low-grade heat energy has attracted increasing research interest in recent years. Abundant waste heat exists widely inhuman society. Due to the low efficiency of heat utilization, more than half of the thermal energy is dissipated into the atmosphere as waste heat. Additionally, waste heat is inevitably generated during the operation of electronic equipment and mechanical processes. Most of this waste heat is low-grade heat with a temperature below100 °C. Recycling low-grade heat is significant for sustainable development. Among various technologies, utilizing the thermo-electric (TE) effect, characterized by direct heat-to-electricity conversion, is considered one of the most promising methods for recovering low-grade heat from different real-world situations. Nowadays, TE technology must not only produce high power densities but also be efficient, scalable, cost effective, and suitable for multiple application scenarios. For example, there is a high demand for flexible and robust TE materials for wearable devices and daily life applications.

TE materials can be classified into electronic thermoelectric (e-TE) materials and ionic thermoelectric (i-TE) materials. e-TE materials, although widely investigated for their high conductivity, still suffer from the inherent drawbacks of low Seebeck coefficients (on the order of 10-2 to 10-1 mV K-1), poor flexibility, and high production costs, which severely limit their reliable thermoelectric conversion performance and their applications. In contrast, i-TE materials, such as liquid electrolytes, ionic hydrogels and ionogels. They exhibit high Seebeck coefficients, which are 2-3 orders of magnitude higher than those of e-TE materials, through ion diffusion (also known as the Soret effect), and thus have become important materials for low-grade heat energy harvesting.

i-TE gel-like materials can effectively solve the leakage problem of liquid-based i-TE materials. As a quasi-solid material, Gel effectively prevents liquid leakage. At present, i-TE gel mainly focuses on two types of systems: ionic hydrogel and ionogels. Although ionic hydrogel has high ionic conductivity, they face challenges of extreme environmental adaptability and long-term stability. High temperatures can cause water evaporation, while low temperatures may lead to freezing, resulting in mechanical property deterioration and TE performance attenuation. Deep eutectic solvents (DESs) have garnered significant attention as an emerging class of green solvents, offering more environmentally friendly, cost-effective, and nontoxic. DESs also exhibit low vapor pressures, high conductivity, and strong solvation toward ionic and nonionic compounds. They have been utilized in various fields, particularly in electrochemical energy storage and conversion. Consequently, DES-based gel materials, referred to as eutectogels, often exhibit excellent properties, including high stability, strong adhesive strength, good conductivity, and notable strength and flexibility.

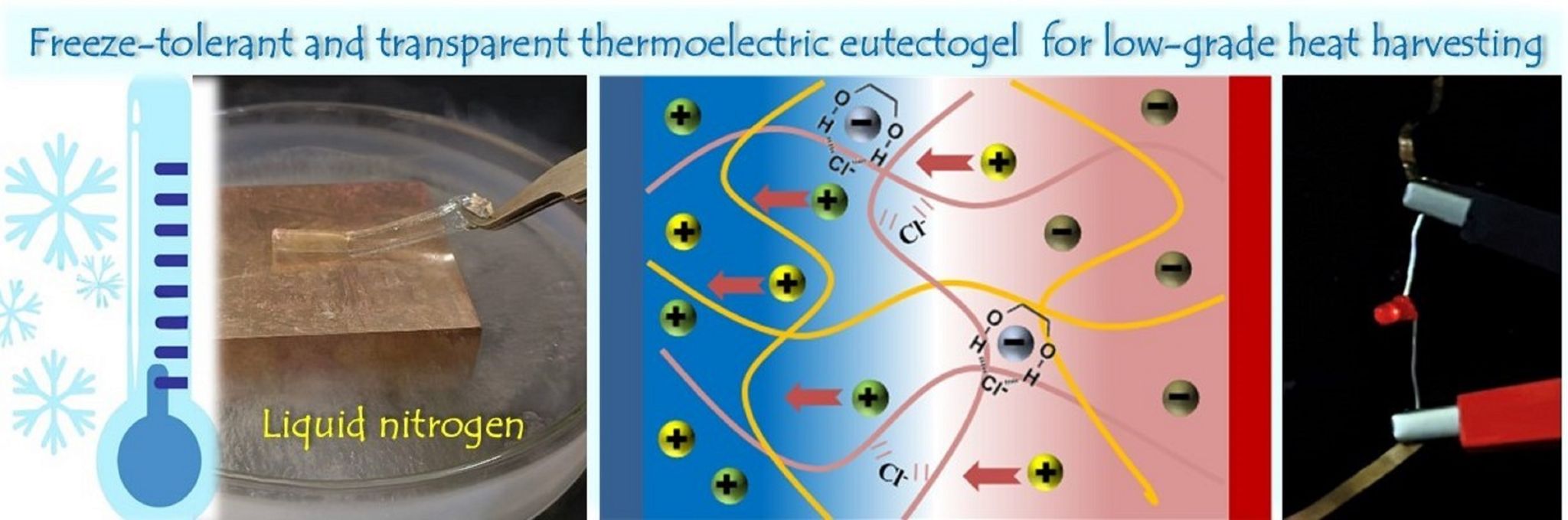

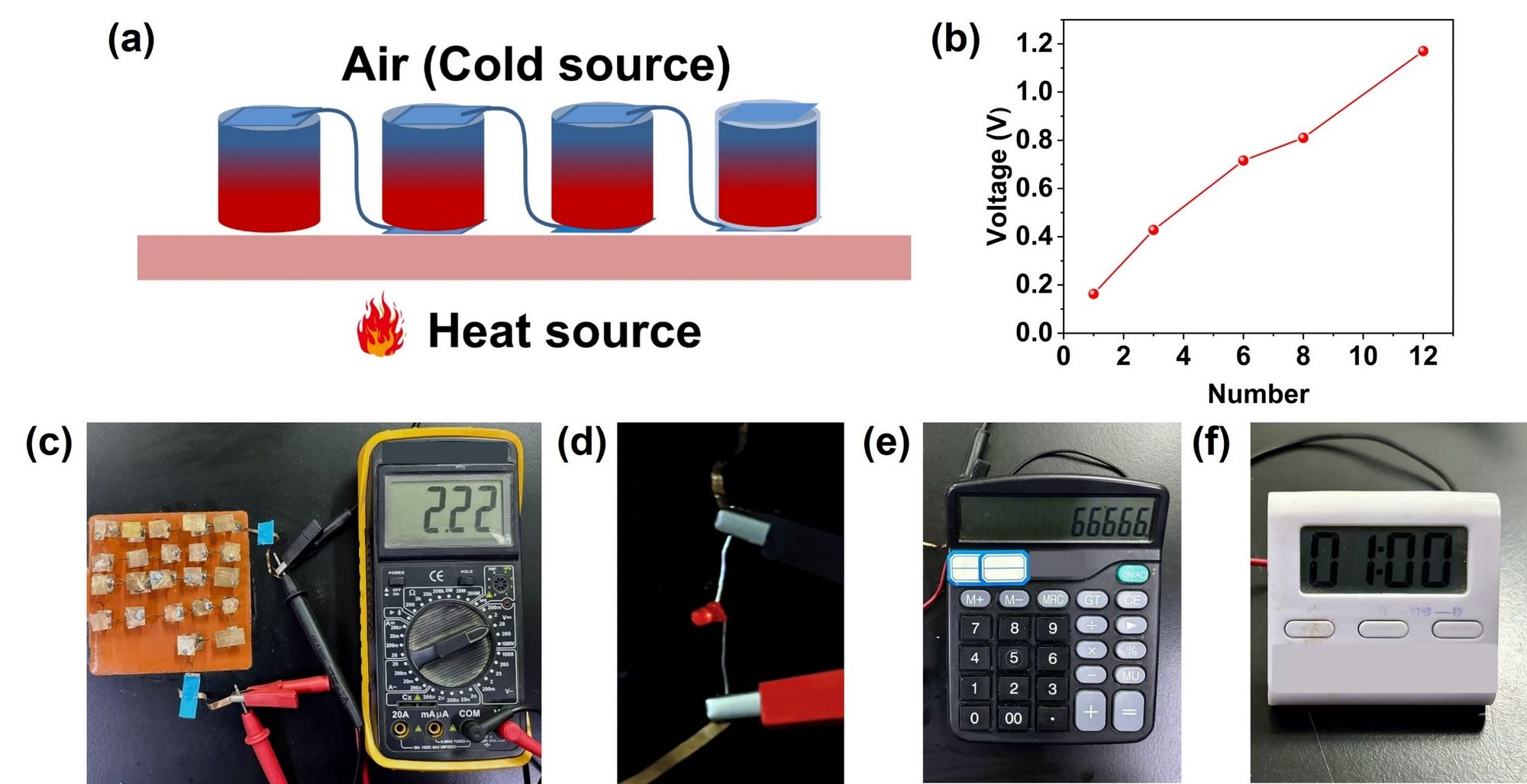

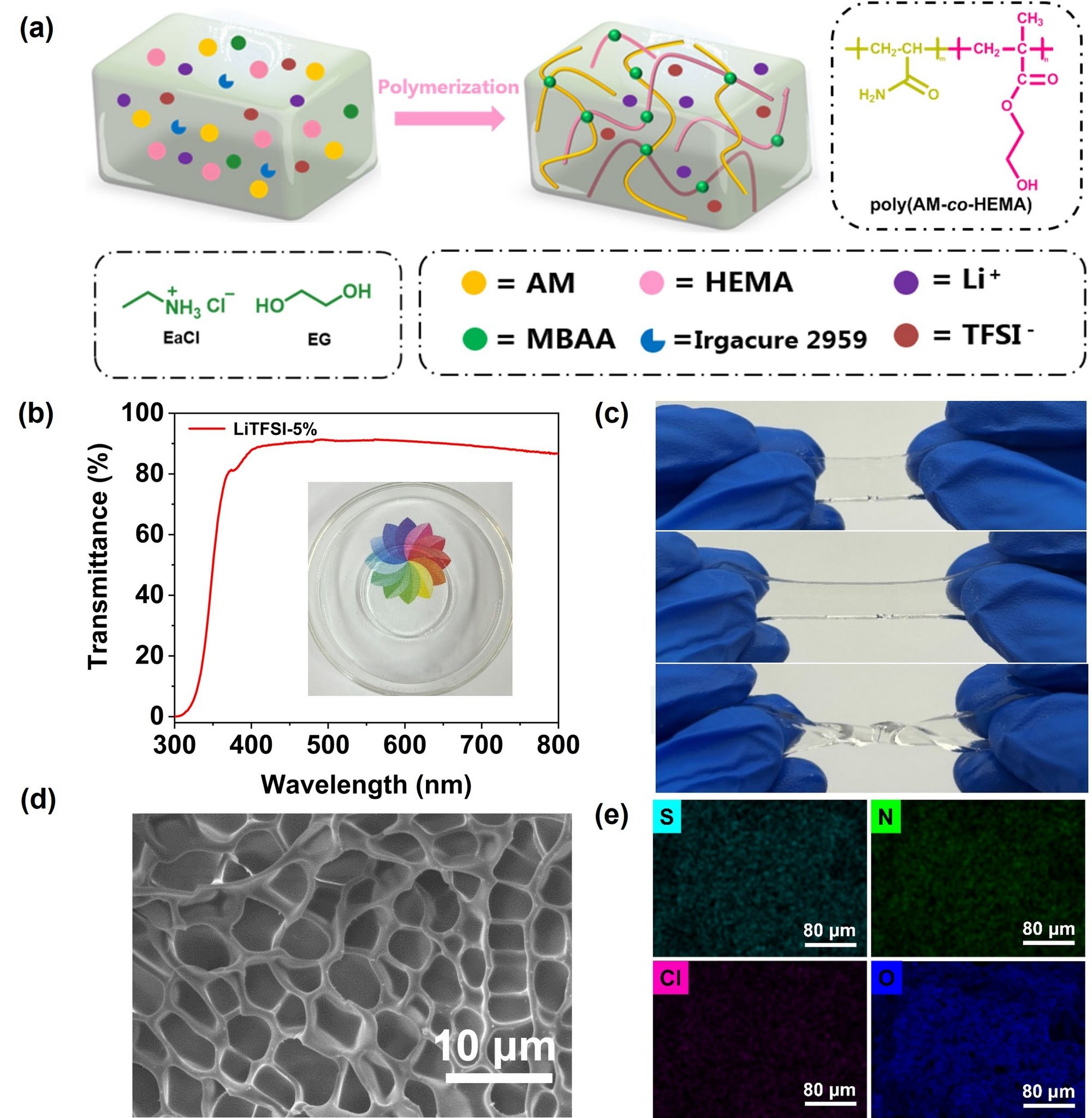

Herein, we present a highly transparent polymer eutectogel comprising a green deep eutectic solvent (DES) along with lithium salt. This eutectogel exhibits a high ionic conductivity of 20.2 mS cm-1 and ionic Seebeck coefficient of 9.7 mV K-1. Thanks to the excellent freeze-resistant property of DES, the ionic conductivity can still reach 7.6 mS cm-1 even at -20 °C. Additionally, the interaction between polymer network and DES prevents crystallization within as prepared eutectogel, instead resulting in a glass transition at -114 °C, slightly higher than the freezing point of DES at -113 °C. Furthermore, as prepared eutectogel demonstrates exceptional long-term solvent retention, showing no weight loss when exposed to ambient environment (~23°C, ~60% RH) for 7 days, and maintaining 90 % of its weight after being placed in an oven for 1 day (50°C, ~30% RH with strong air circulation). As prepared eutectogel also shows excellent stability of thermoelectric performance over a wide range of the relative humidity. The homemade device utilizing as prepared eutectogel shows the potential to directly power some small electronic devices (such as light-emitting diode and timer) and to recover wasted heat generated by solar panel. Our results provide a foundation for the development of bio-friendly TE gel-like materials that exhibit outstanding environmental tolerant and long-lasting usability.

Figure 1. Preparation and characterization of the PAH-5% LiTFSI eutectogel.

Figure 2. Thermoelectrical applications of the eutectogels.

First Author: Zhi Yaolong, master’s student, Shaanxi Normal University

Correspondence Author: Prof. Peng Junxia, Shaanxi Normal University

Full Text Link: https://doi.org/10.1021/acsapm.5c00097

Latest Updates

Latest Updates